In the modern industrial landscape, the manufacturing sector is undergoing a revolutionary transformation, becoming more data-centric than ever before. Empowered by advanced Enterprise Resource Planning (ERP) systems and Internet of Things (IoT) sensors, manufacturers are amassing vast volumes of data, gaining valuable data insights to fuel informed decisions that catalyse productivity, enhance efficiency, and nurture substantial growth.

This article delves deep into the strategies through which manufacturers can harness data analytics and reporting, propelling them into a realm of competitive advantage.

Harnessing Data Insights for Informed Decision Making

Central to the manufacturing data revolution is the capability of Enterprise Resource Planning (ERP) systems to collect and synthesize invaluable data spanning sales, inventory, production, quality control, maintenance, and more.

These data sets, when subjected to meticulous analysis via integrated analytics tools, unveil hidden trends and patterns that hold the key to operational optimisation.

Leveraging Data Insights

Manufacturers are capitalising on data insights in multiple ways, including:

- Identifying Production Inefficiencies: Analytics spotlight bottlenecks in production workflows, driving targeted process improvements.

- Streamlining Supply Chains: Manufacturers locate and alleviate supply chain bottlenecks, ensuring seamless operations.

- Accurate Inventory Forecasting: Predictive analytics aid in anticipating future inventory needs, averting stockouts and overstock situations.

- Forecasting Sales Dynamics: By analysing historical sales data, manufacturers can predict trends and anticipate demand fluctuations.

- Enhancing Equipment Efficiency: Overall Equipment Effectiveness (OEE) metrics are tracked to maximise machinery output.

- Ensuring Quality Metrics: Data insights and analytics monitor key quality parameters, preventing defects and ensuring product excellence.

The Transformative Role of Data Reporting:

While data analytics unearths insights, data reporting is the conduit that translates these insights into actionable strategies. Enterprise Resource Planning (ERP) systems centralise data, and reporting tools organise this data into comprehensible dashboards, visualisations, and documents.

Key Reporting Metrics:

Critical metrics for manufacturers encompass:

- Operational Efficiency: OEE, cycle times, and throughput metrics are vital indicators of production effectiveness.

- Quality Management: Scrap, rework, and yield rates gauge the efficiency of quality control processes.

- Financial Insights: Cost per unit and margin analysis offer insights into the financial viability of manufacturing processes.

- Resource Utilisation: Capacity utilisation percentages illuminate the efficient utilization of resources.

- Inventory Management: Inventory turns and days-on-hand metrics optimise inventory levels for cost-effectiveness.

- Order Fulfilment: Customer order cycle times are pivotal for timely delivery and customer satisfaction.

- Supply Chain Efficiency: Supplier lead and lag times influence the efficiency of the supply chain.

Reports Tailored for Leadership

Reports should be designed to cater to different leadership levels within the organisation. Real-time dashboards empower teams to monitor Key Performance Indicators (KPIs), while data visualisation provides rapid insights.

This approach fosters transparency and informed decision-making across the organisation.

Unlocking Agility through Real-Time Data

Traditionally, manufacturing data was employed retrospectively for long-term enhancements. However, the paradigm is shifting towards real-time data applications that drive agility. Enabled by IoT sensors, automated data collection, and integrated systems, manufacturers can now harness real-time insights for instant, strategic decision-making.

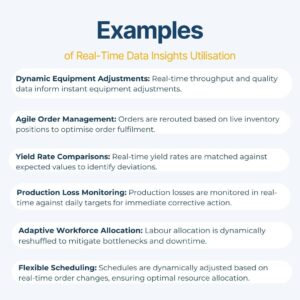

Examples of Real-Time Data Insights Utilisation:

Elevating Competition through Data-Driven Strategies:

Forward-thinking manufacturers recognise data insights as an invaluable competitive asset. By leveraging data insights from ERP systems, organisations can:

- Propel Productivity through Process Enhancements: Insights garnered from data analysis lead to process optimisation.

- Slash Costs by Eliminating Inefficiencies: Data-driven insights unearth inefficiencies, reducing operational costs.

- Enhance Quality by Proactive Issue Resolution: Timely data insights enable proactive quality management.

- Boost Capacity through Bottleneck Identification: Data insights highlight bottlenecks for targeted capacity enhancements.

- Optimise Inventory via Demand Forecasting: Precise demand forecasts lead to leaner inventory management.

- Delight Customers with Reduced Lead Times: Data-informed decisions streamline operations, leading to shorter lead times.

- Flexibility in Operations: Data-backed strategies empower manufacturers to adapt to changing circumstances.

The Imperative of Data-Driven Decision Making

In the present-day manufacturing landscape, data insights and analytics are no longer a choice – it’s a prerequisite for attaining success. Manufacturers that fail to embrace data-driven decision-making run the risk of lagging behind competitors.

Conversely, those who embrace this paradigm will harness the power of data, optimising operations, and outperforming their peers. Data paints the landscape of intelligence and visibility, shaping the trajectory of manufacturing excellence.

Join our LinkedIn community for the latest industry trends and SAP news! Connect with professionals, access exclusive content, and stay updated on dynamic business and technology realms. Elevate your knowledge by joining us on LinkedIn and be the first to access thought-provoking articles and exciting updates!