The manufacturing industry is undergoing a renaissance driven by the immense potential of ERP automation. Optimising processes, reducing manual efforts, and accelerating innovation, this technology is unlocking a brighter future.

The Automation Revolution Streamlining Manufacturing workflows

ERP (Enterprise Resource Planning) systems are integral in revolutionising manufacturing operations. By automating repetitive and routine tasks, ERP systems allow manufacturers to achieve new levels of efficiency and productivity.

Automating inventory management, production scheduling, quality control processes and more eliminates the need for tedious and time-consuming manual work. Workers are free to focus their efforts on more impactful initiatives like process improvements, maintenance, and customer service.

Advanced algorithms in ERP systems can even optimise production sequences and inventory levels dynamically based on real-time data. This level of intelligent automation is transforming workflow agility and responsiveness across the manufacturing floor.

The Widespread Benefits of Leveraging ERP Automation

The benefits of embracing ERP automation are far-reaching:

- Streamlined Processes – Automating workflows enhances process speed, reduces waste and boosts overall equipment effectiveness.

- Less Manual Work – Automation can decrease manual efforts by over 40%. This allows the redeployment of workers to higher value tasks.

- Improved Quality – By standardising automated processes, manufacturers can achieve more consistent, high-quality output.

- Enhanced Visibility – Automated data collection from machinery, inventory, etc. provides real-time operational visibility via dashboards.

- Higher Output – Optimised workflows and machine coordination drives increased throughput and productivity.

- Lower Costs – Reduced wastage, errors and labour costs enabled by automation improve profitability and cost savings.

These quantified gains demonstrate the tremendous value ERP automation brings to manufacturing operations.

Transforming Production Through Automated ERP Processes

A core benefit from ERP automation is the transformation of production operations. Automating key steps in the production sequence brings higher precision, speed and efficiency.

For example, automated inventory checking and re-ordering ensures required materials are always stocked. Intelligent algorithms can schedule jobs and coordinate machines to optimise flow.

Real-time data collection from sensors and equipment provides insights into work in progress, output rate, deviations etc. Issues can be addressed swiftly before impacting production.

Automated processes also enable ‘lights-out’ manufacturing with minimal human intervention. Consistent and rapid production is maintained 24/7 through the automated system.

By minimising manual work, manufacturers achieve more reliable, efficient and cost effective production. Worker efforts are directed at more rewarding tasks like data-driven improvements.

Leveraging Data for Smarter Decision Making

ERP automation enhances data management and analytics capabilities enormously. The system can seamlessly gather data from all connected manufacturing systems and equipment.

Advanced analytics and reporting digest this data into actionable business insights. Historical data aids in forecasting demand, inventory needs, and optimal resource allocation for production plans.

Real-time dashboards provide end-to-end visibility across the operation, enabling data-driven decisions at each step. Issues can be rapidly identified and addressed before escalating.

With an ERP system serving as the digital thread connecting all manufacturing data, smart data utilisation becomes a key competitiveness factor.

Pioneering Innovation Through Automation

One of the most exciting outcomes of ERP automation is freeing up resources for innovation initiatives. Eliminating repetitive manual work enables teams to focus on value-adding projects.

Manufacturers can leverage this opportunity to experiment with cutting-edge technologies like AI, 3D printing, cobots, etc. The future competitiveness of manufacturing will rely heavily on such innovation.

The rich data and insights from ERP systems also inspires innovation. Identifying potential improvements through data analytics motivates manufacturers to push boundaries and try new approaches.

With innovation accelerating, ERP automation paves the way for next-generation smart factories. This transformation will define the manufacturing landscape of the future.

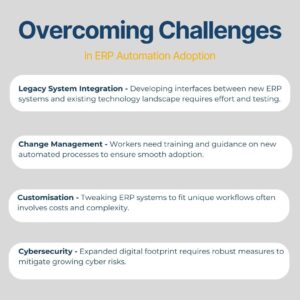

Overcoming Challenges in ERP Automation Adoption

While the benefits are compelling, ERP automation also poses some challenges that manufacturers must address

With careful planning, adaptation and investment, manufacturers can systematically tackle these challenges on their automation journey.

Unlocking the Future with Automated Manufacturing

In conclusion, the realm of manufacturing is on the brink of an extraordinary transformation, and at its heart lies the power of ERP automation. By integrating cutting-edge automated processes into manufacturing operations, companies can propel themselves towards unprecedented levels of quality, output, consistency, and profitability. The days of labour-intensive tasks and human error are fading, making way for streamlined, optimised processes that require minimal manual intervention.

Seize the Opportunity: Embrace ERP Automation Now!

The journey towards a new era of manufacturing excellence begins with embracing this automation revolution. Forward-thinking manufacturers hold in their hands the key to unlocking a world of possibilities. Through this powerful technology, innovation is accelerated, efficiency is elevated, and operations become not just responsive but predictive, fuelled by data-driven insights.

Secure Your Manufacturing Future

The time is now to seize the benefits that ERP automation unleashes. Don’t be left behind in the wake of this transformative wave. Join the pioneers who understand that the future belongs to those who act today. Embrace automated manufacturing and propel your business into a realm where growth knows no bounds. Click here to schedule a consultation and take the first step towards building the responsive, efficient, and data-driven operations of tomorrow.

Follow us on LinkedIn to stay ahead with industry trends and SAP news! Join our vibrant professional community for invaluable insights into the ever-evolving worlds of business and technology. Don’t miss exclusive content, thought leadership articles, and thrilling updates. Connect with us on LinkedIn today and enhance your industry expertise!