The One for Manufacturing Growth: Scaling Your Operations with SAP Business One

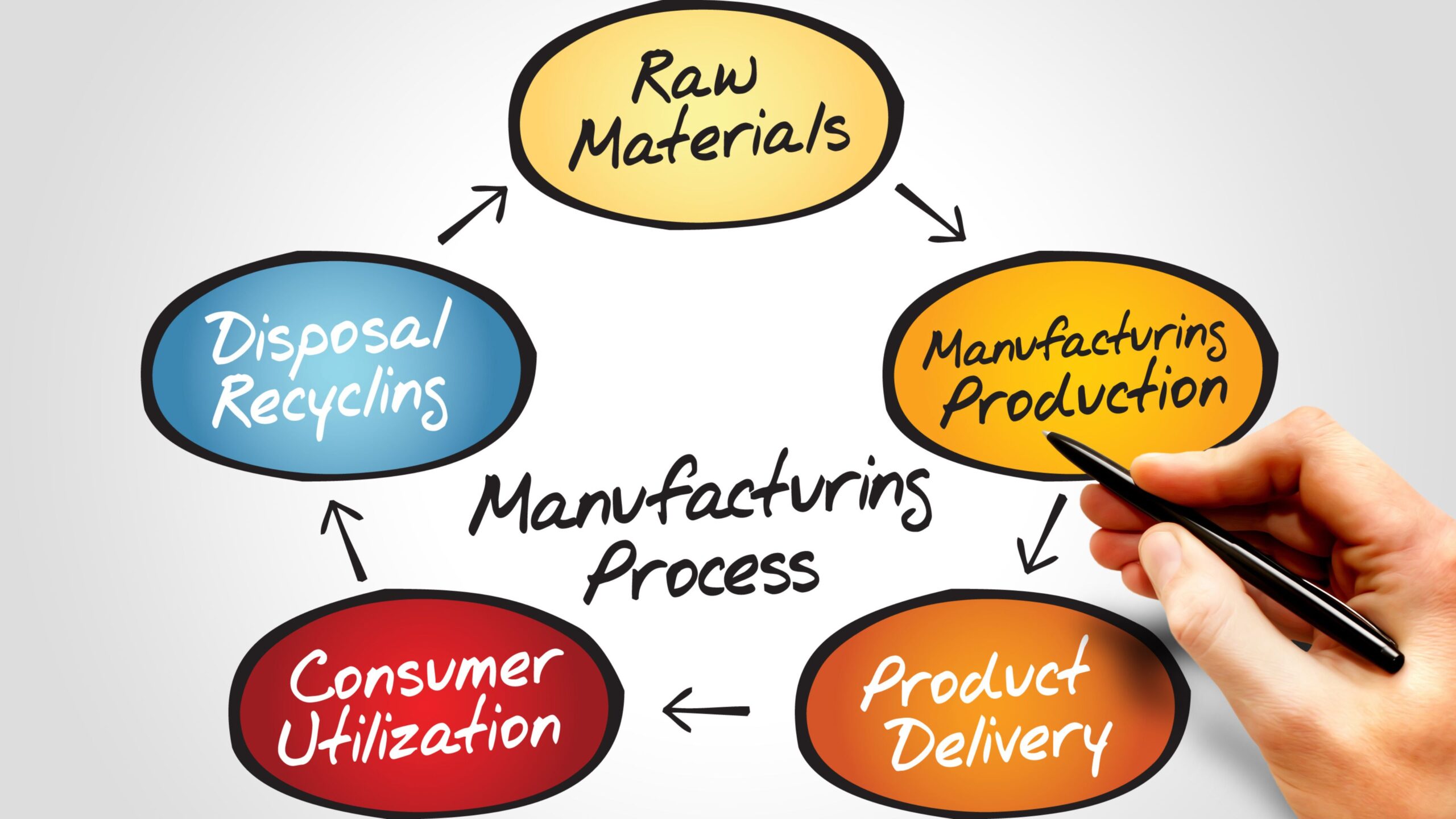

Achieving Your Manufacturing Growth Aspirations Your aspirations for manufacturing growth hinge on the scalability of your operations. SAP Business One stands as a robust ally, tailoring its capabilities to the unique tempo of your business expansion. It’s not just about growing; it’s about growing smartly and sustainably. As you aim to scale your operations, the […]

Diane Harvey